HOPPE (UK) shares some of the questions that its technical teams are asked about fire doors and offers advice for specifying compliant door hardware in public buildings…

What hardware do I need?

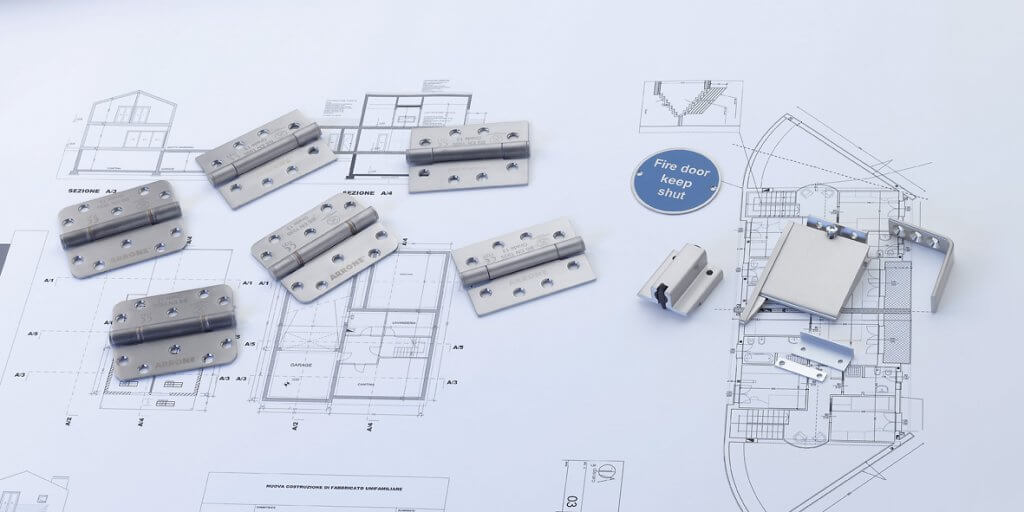

There are three pieces of essential hardware that are critical to a fire door’s performance; hinges, door closing devices and locks. In a fire, these products help to close and secure the door in its frame to allow, in the case of timber fire doors, intumescent protection around the door, frame and hardware to expand and fill gaps around the door.

To conform to EN1154, the smallest door closer that can be used on a fire door is a size 3. The heavier the door, the more powerful the closer must be. The smallest size 3 is up to 60kg and 950mm wide and the largest size 6 up to 120kg and 1400mm wide.

Any hardware that requires the removal of a section of the door leaf or door frame should be fitted with the correct intumescent. Intumescent seals should also be fitted in line with the door’s fire certification. There should be intumescent wrapped around a lock case and in some cases behind the hinges. This is often missed but can be checked by simply removing the lock case or hinge.

Where is panic and emergency exit hardware used?

Panic or emergency exit hardware may be needed depending on the building’s type, application, its occupation levels, and where the door is in the building. For fire doors on an escape route, panic or emergency exit hardware is mandatory.

Emergency exit hardware is mainly used in buildings where users are familiar with exit routes and are not accessible to the public. This could be a simple push pad type device or a lever handle operating a mortice escape lock or nightlatch.

Panic hardware is used when the general public has access to the building and may not be familiar with the exit routes. This applies to any room with a capacity of over 60.

Any doors in areas that are accessible to the public must have a device fitted that is operable by a horizontal bar that covers at least 60% of the overall door width to make it easier to see and use. It also adds another layer of safety functionality in an emergency.

What do I need to consider for refurbishment projects?

When replacing fire door hardware, the new components must be equal to or better than the fire/mechanical performance of the door.

To tell if a product is ‘like for like’, look at the tested elements and the certification for the products. Check what type of door the ironmongery is tested for use on. A product that has been fire tested for use on a timber door is not necessarily suitable for use on a steel door and vice versa (without prior testing on that type of door).

Remedial work should not include removal of intumescent materials from the door, unless damaged. Any replacement of hardware intumescent kits should be the exact same material and thickness.

If in doubt about any fire door hardware, consult with the original door manufacturer or contact HOPPE (UK) for advice on 01902 484 400. www.hoppe.com